- Home >

- Food Microbiology Extended

Food Microbiology Extended

Beyond traditional methods

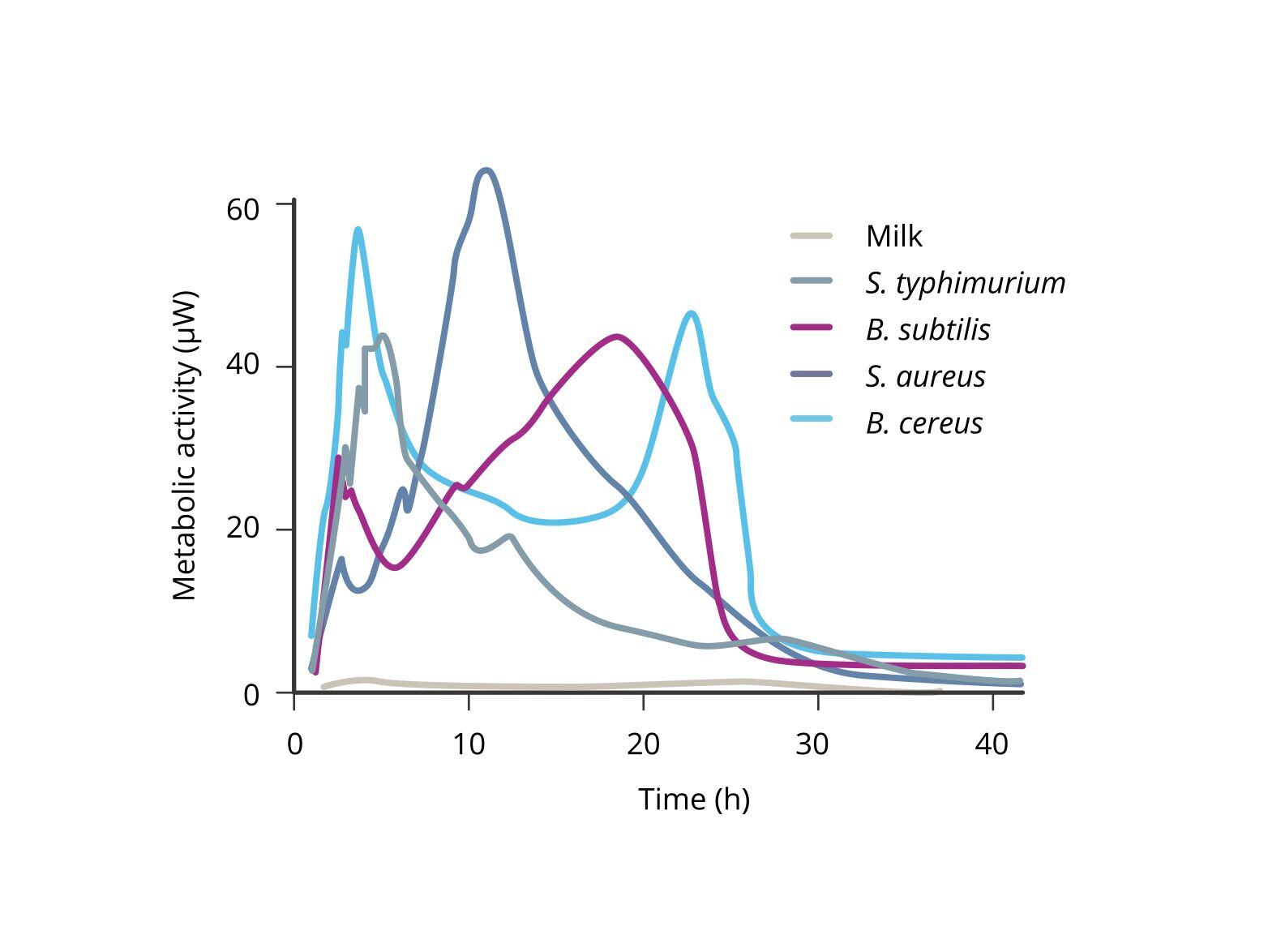

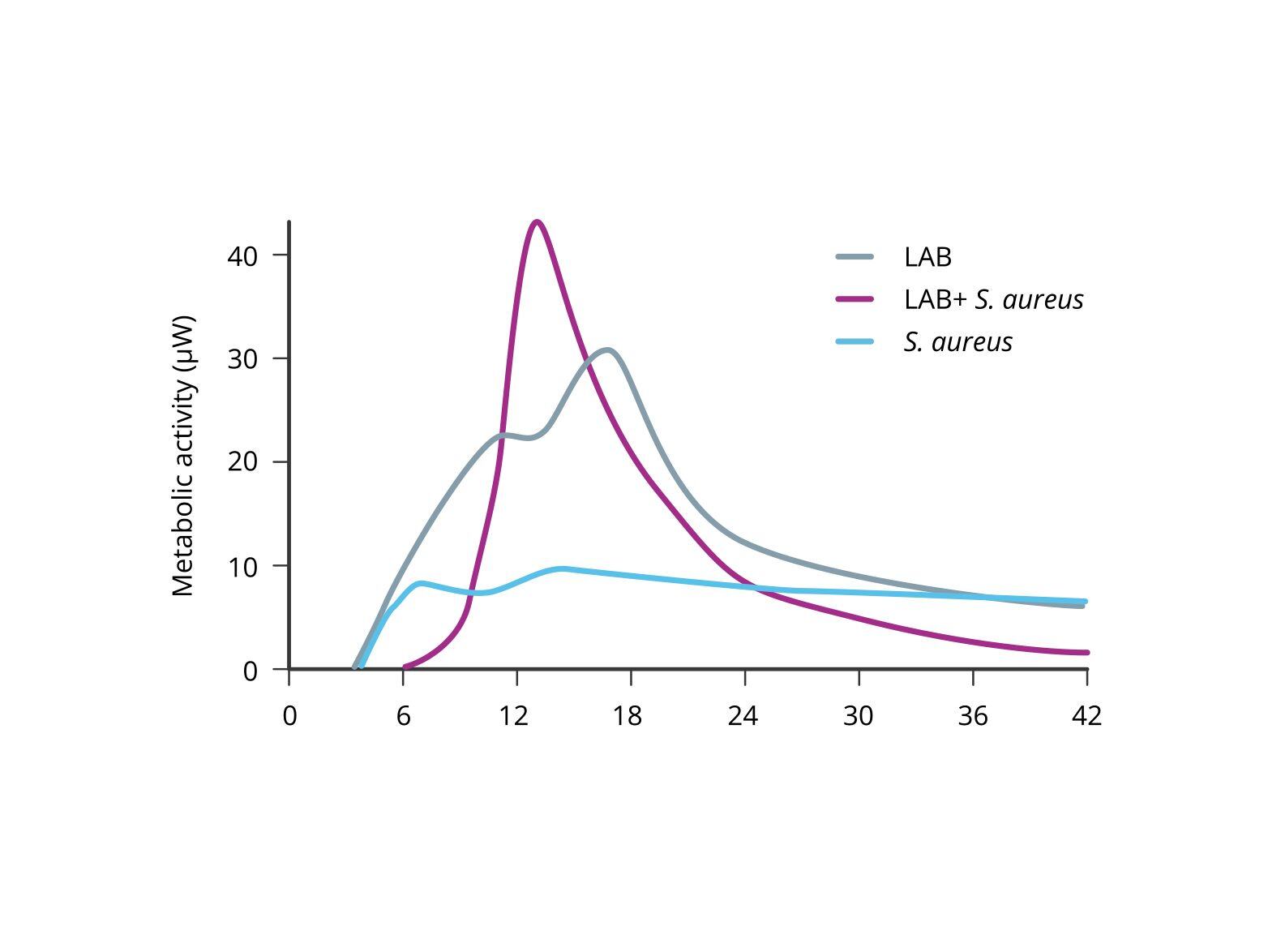

Detecting microbial contaminants in food ingredients and products is tricky, as they are often embedded deep within the product. Traditional techniques tend to be cumbersome, requiring extensive hands-on time and sample preparation and can produce false positives or negatives, leading to potentially serious consequences.

There is a need for a fast and highly sensitive method that can detect microbial levels, no matter where they are located within a product. This method should require minimal hands-on sample preparation to reduce the risk of contamination and error. Additionally, it would be highly beneficial if this technique could differentiate between harmful foodborne pathogens and the normal flora naturally present in the product.

The Symcel calScreener™ solves these issues. It detects contaminants deep inside even the most complex food products with minimal hands-on time. There’s no need for extensive sample preparation, which significantly reduces the likelihood of false negatives or positives. Moreover, the calScreener™ delivers very fast results, often within hours, which can dramatically shorten the time needed to release products to the market.

Food safety testing becomes more efficient, accurate, and reliable, helping to ensure that products meet the highest standards of safety before reaching consumers.

Need for speed

Some food products are particularly perishable, with very short shelf lives, so that timely release to the market is crucial. However, the process of microbial and quality control testing can be time-consuming, resulting in delays that not only extend the release time but also increase the need for costly warehouse space. Traditional methods, such as plate and broth cultures or even some molecular techniques, simply take too long to be practical for these time-sensitive products.

To meet this challenge, we need a fast, highly sensitive method for detecting microbial levels, regardless of where the microbes are located within the product. This method should be significantly quicker than traditional techniques, allowing for rapid decision-making and faster release times.

The Symcel calScreener™ detects contaminants deep inside even the most complex food products, with minimal hands-on time required. It provides rapid results, often within hours, significantly reducing the time to market while retaining freshness and with a minimal need for storage.

Microbial load detection

Detecting microbial load in non-sterile products like ground meat is tricky. Traditionally, the process requires time-consuming removal or amplification of bacteria from the product to be counted using either plate counting or Q-PCR. It is often random and inconsistent in ensuring the removal of all bacteria are removed, and even when bacteria are successfully extracted, some may be viable but not culturable on plates, leading to inaccurate counts and assessments.

We need a reliable method for assessing microbial load directly within non-sterile products. This would help prevent spoilage by providing accurate microbial counts without the need for complex and error-prone removal processes.

The Symcel calScreener™ lets you directly measure microbial load within the product, eliminating the need to remove bacteria for plating. As a result, all bacteria, including those that might not grow on traditional culture media, are detected accurately, reflecting the microbial load.

Preventing contamination

There are few things in the food production industry more important than maintaining clean, sterile production facilities. However, if contamination occurs, the testing process for sterility after cleaning can be lengthy and costly. Production lines remain idle while waiting for microbial testing results, leading to significant financial losses. The problem is further compounded if the testing methods fail to detect every microbial cell, as this can lead to a reappearance of contamination shortly afterward. Traditional methods often miss viable but non-culturable cells, which means that even after thorough cleaning, the risk of contamination persists.

To ensure production lines’ integrity and minimize downtime, we need a super-fast method for detecting all microbial contaminants production facilities. The method should be an all-in-one solution that provides rapid results and is sensitive enough to detect even a single microbial cell. It must also be capable of identifying a wide range of microbes, including bacteria, yeast, molds, and spores, to guarantee thorough cleanliness.

The Symcel calScreener™ can detect single microbial cells in clean facilities, ensuring no contaminants are overlooked. The calScreener™ is remarkably sensitive and can quickly detect all types of microbes, including slow-growing bacteria, anaerobes, spores, molds, and yeast. With the calScreener™, you can drastically reduce downtime and operate with confidence, knowing that your lines are truly sterile and ready for use.